ENERGY RECOVERY FOR OPTIMIZED DOAS PERFORMANCE

Not only is energy recovery an effective way to reduce operating costs in high outdoor air HVAC systems, but its use is also often required by state energy codes and standards.

WHERE IS EXHAUST AIR ENERGY RECOVERY REQUIRED?

Each state has its own requirements for energy efficient construction of new buildings, additions, and retrofits. The two most common sources included in state building codes are ASHRAE 90.1, Energy Standard for Buildings Except Low Rise Residential Buildings, and International Energy Conservation Code (IECC) which adopts most of the ASHRAE 90.1 language and requirements. Each is updated every three years.

The requirement for exhaust air energy recovery promotes energy efficient design where certain favorable criteria exist. The current requirement considers:

- Supply airflow and outside airflow of the system

- Climate where the project is located

- Number of annual operating hours

The line is drawn between systems operating less than 8,000 hours per year, and systems operating 8,000 hours or more per year. Where exhaust air energy recovery is prescribed, an enthalpy recovery ratio (ERR) of 0.5 is required, defined as the change in the outdoor air enthalpy divided by the difference between the return air entering enthalpy and outside air entering enthalpy.

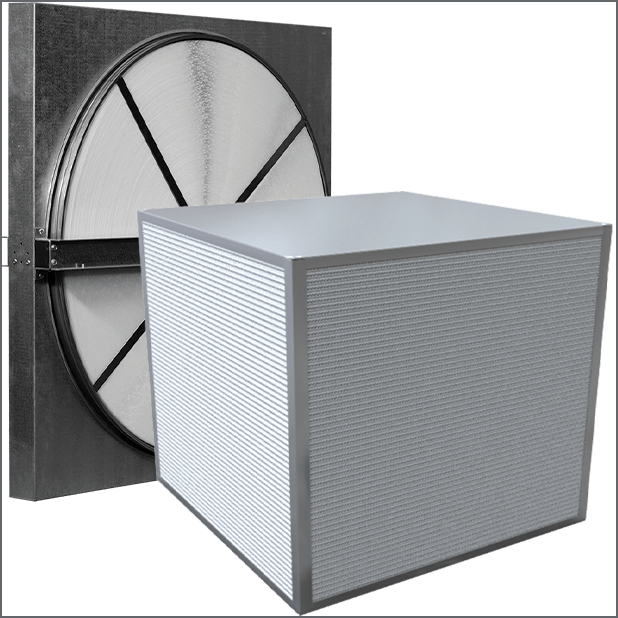

Whether it’s a highly efficient energy recovery wheel or a low maintenance core, Valent offers a wide variety of energy recovery options.

Download the Energy Recovery Application Guide or visit our Applications Expertise page to learn more.

High outdoor air ventilation can mean high cooling and heating loads on HVAC equipment. Energy recovery technologies like cores and wheels can help increase system efficiency.